overview

the repair of cracks on parts or broken parts from grey cast iron is accomplished with application of a special latch plate technology.

the cast parts do not have to be heated up, as necessary for professional welds.

the cast latching is a cold repair technology where, in relation to welds, heat tensions are excluded.

the latch plate technology can be applied on rough as well as on finished cast parts.

the used latch plates are caulked into geometrically fitting recesses transverse to the crack configuration.

by caulking the latch plates with a special high-quality nickel alloy with a tensile strength of 600 - 700 N/mm², the original component strength is recovered, with full accesibility of the damaged spot.

latch plate material

depending on the crack configuration and geometry of the construction unit the individual latch plates will be cut into sections.

arrangement and depth

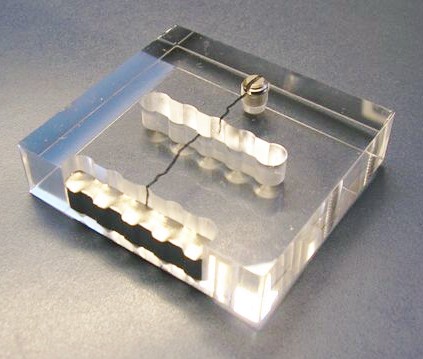

the glass model shows, in wich arrangement and depth to the crack, the latch plates are inserted and caulked into the base material.

the crack initiation and the crack end is drilled out and a threaded bolt is set and caulked.

example: housing crack

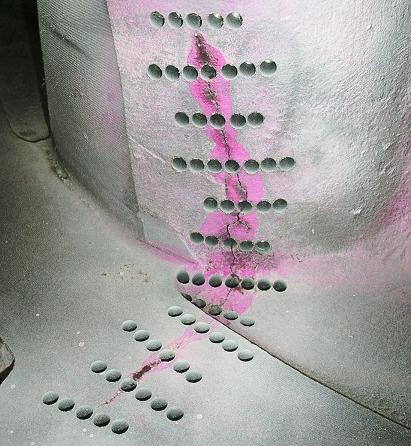

the picture shows a crack at a transmission case, which developed as consequence of a bearing damage.

latch plate drillings

the arrangement and number of bores for the latch plate recesses are predrilled on the necessary depth.

latch plate recesses

as subsequent action, the bars, located between the drillings, are chiseled out in depth to achieve a geometrically defined form.

caulked latch plates

subsequently the prefabricated latch plates become, if necessary also several one on top of the other, assigned and caulked layer by layer to achieve a form- and forceclosed connection.

grinded repair area

the picture shows the repaired housing after completion.

the surfaces of the assigned latch plates are grinded accordingly to the housing outline.

connecting areas are restored according to the original requirement.

on parts, which have a tightness requirement within the crack area, the latch plates are inserted and caulked additionally with two-component adhesive.

to achieve the required tightness, between the latch plates along the crack, closed up screw mountings with adhesive will be screwed in and caulked.

example: housing cracked through a sealing surface.

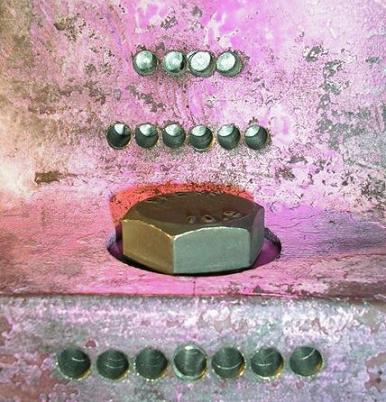

the picture shows a crack through a housing with a sealing surface,

which has been repaired as described with latch plates

and screw mountings.

the picture shows the restored, fully functional sealing surface.

the cast latching is regarded in far circles of experts of different industry branches as the best repair method for cracked or broken construction units made of grey cast iron, and an established procedure well proven over decades. |