here you can see different repair examples:

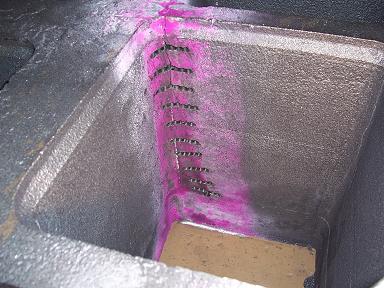

transmission case broken, transmission case cracked

recesses manufactured. over the sealing surface.

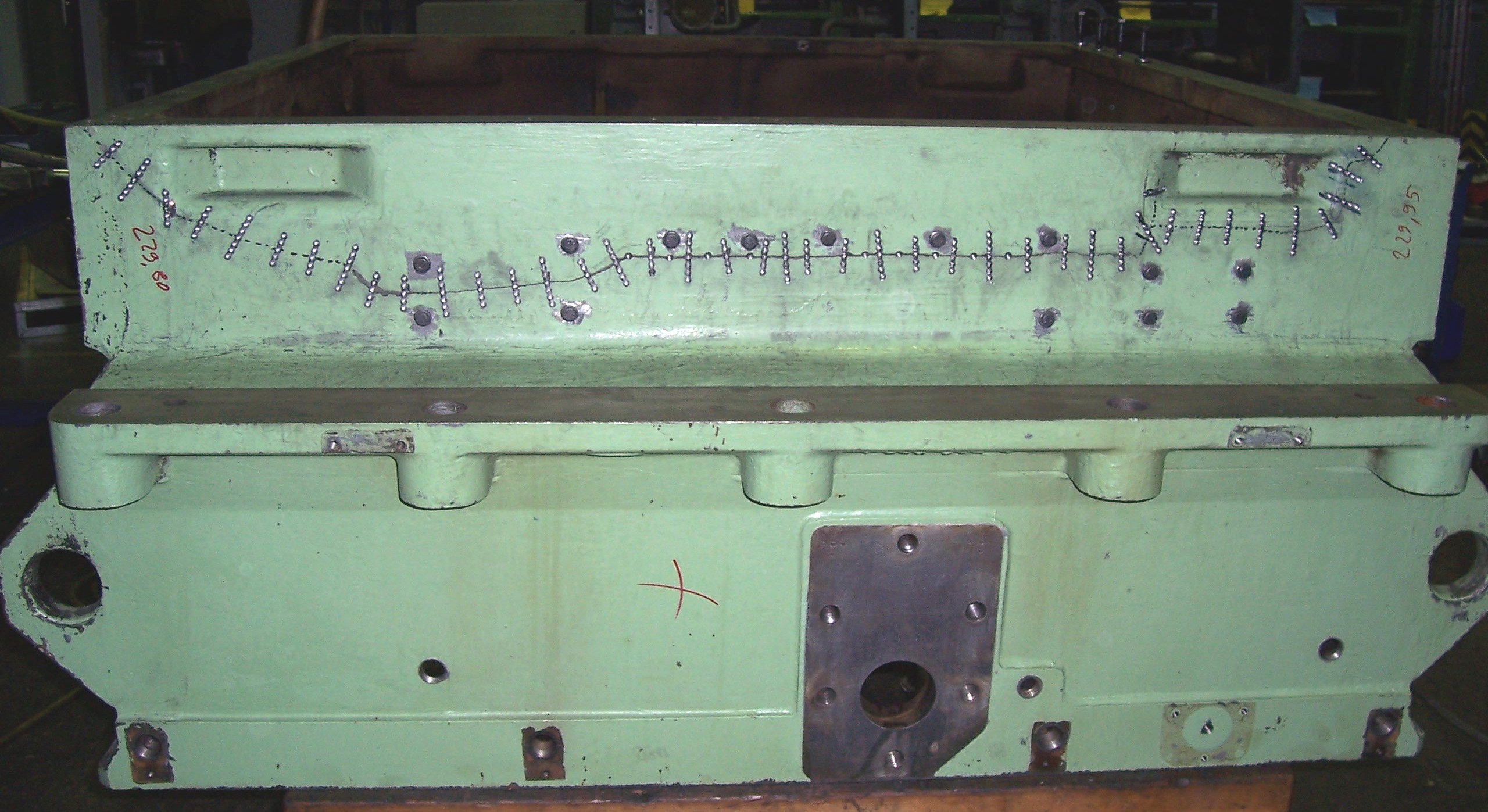

machine table at the lower side at two bars broken. latch plate arrangement bored.

flywheel at a sawing machine on two places cracked.

latch plate arrangement bored, some latch plates already caulked.

crack in a transmission case before and after the latching treatment.

latch plate arrangement bored.

pressmachine stamp at both side-bars to over the center cracked.

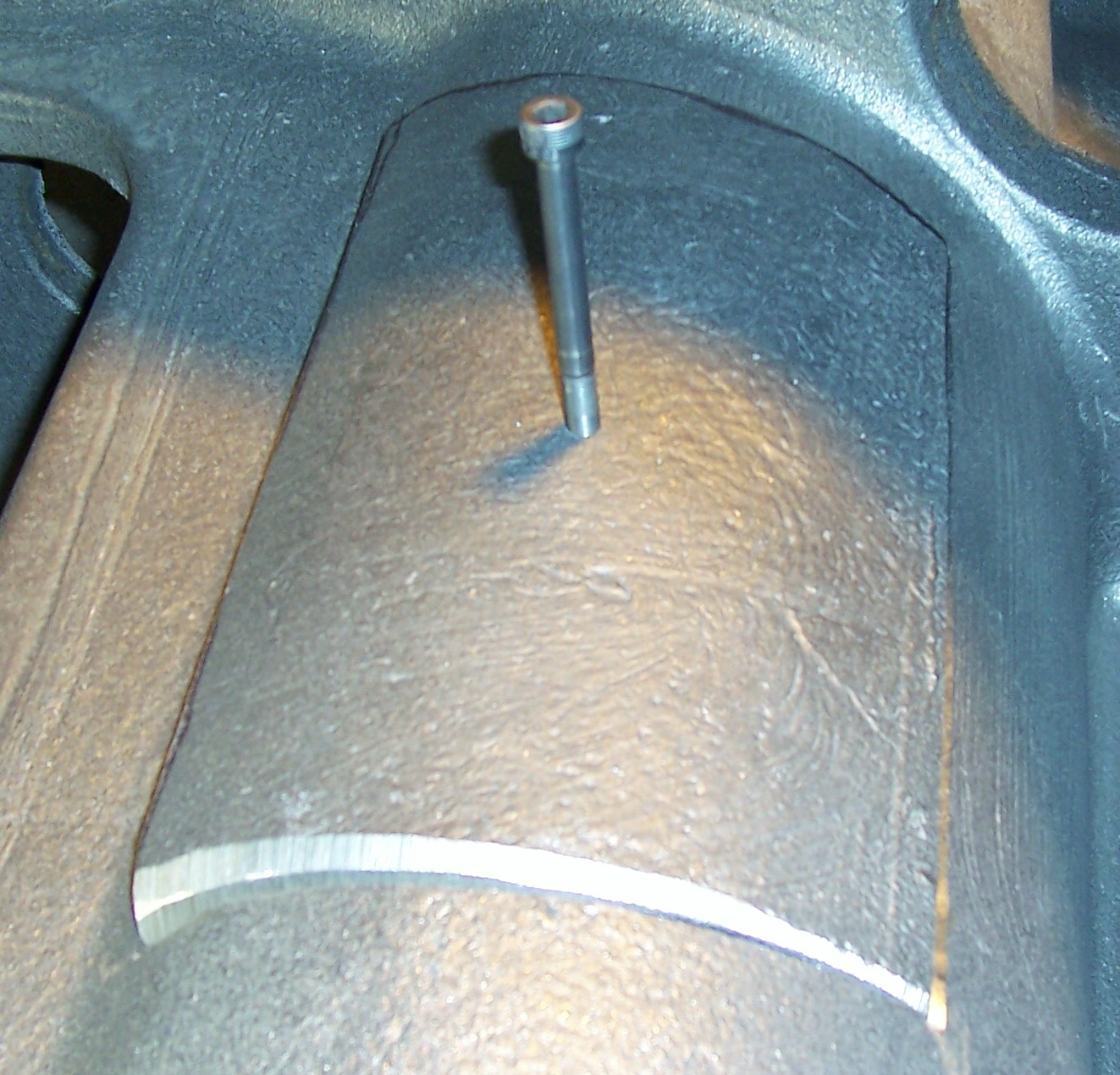

small pressmachine stamp with circular guide

up to a third of the cross section cracked.

by strutting during the latch plate procedure

a remachining at the guidance has been not

necessary.

the press machine stamp of a 630 tons press,

with a stamp dead weight of 13 tons,

was cracked at the drilling for the admission

of balancing after three sides.

the outside of the stamp as well as the internal side during the latching treatment.

the housing of a speed-coupling transmission was cracked over a length of approx.1,5 m.

the crack had a gap of approx. 10 mm. It was adjusted and fixed.

the crack in the housing was fixed tight after the latching treatment with latch plates and screw mountings.

the tightness-check prooved, that the housing was complete sealed.

broken groove on a maschine bed. part for set in will be prepared.

The part is fixed with latch plates.

screw mountings are screwed in into the

joint between the parts.

after tightness-check, the groove was tight.

the cast thickness is not correct founded. the faulty material was cutted out.

part for set in is prepared and fixed tight with latch plates and screw mountings.

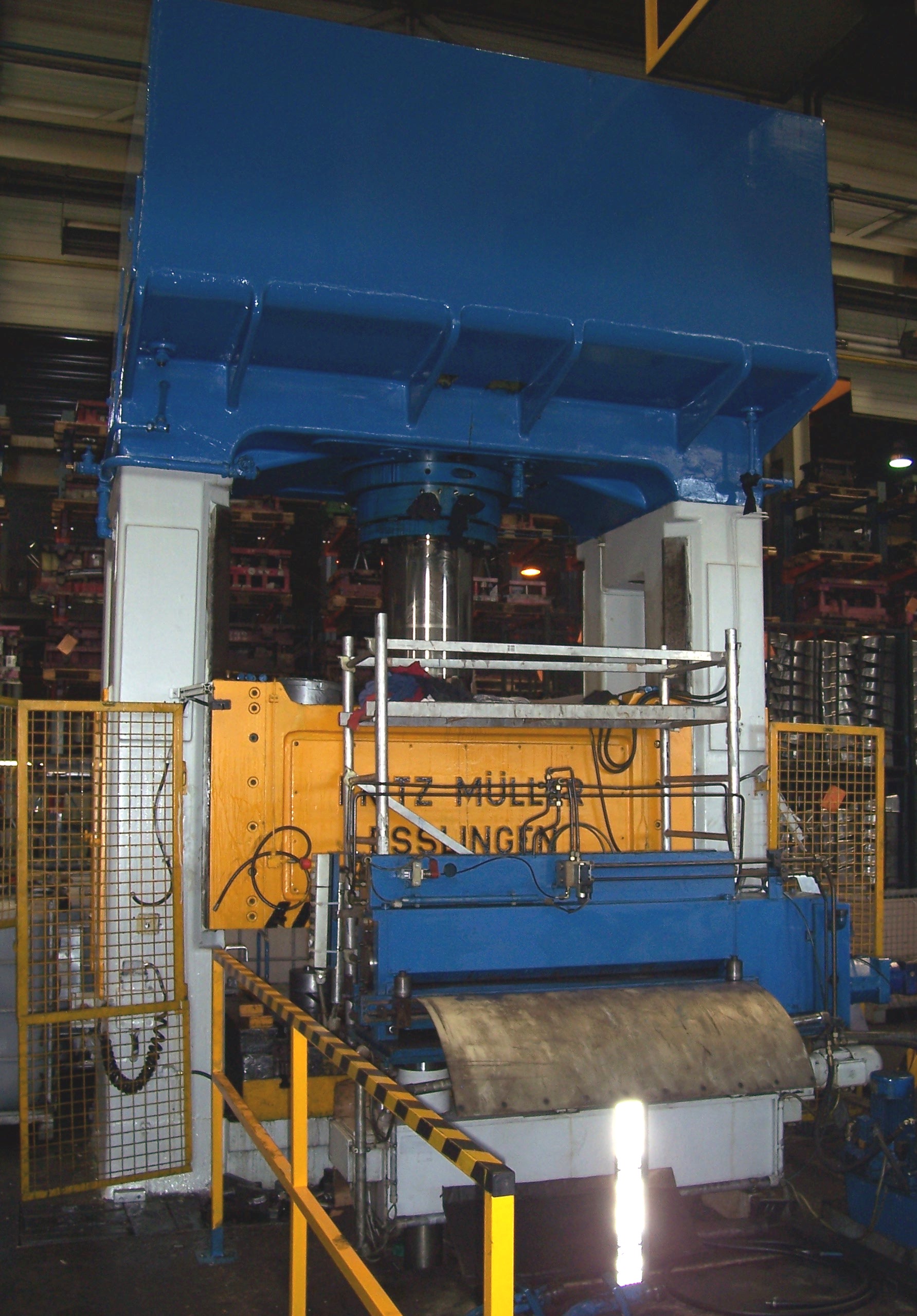

a 800 tons press is cracked in the area of the

admission for the hydraulic cylinder.

after the hydraulic cylinder is removed, it is possible to start the latching repair.

latch plate arrangement on the outside hydraulic cylinder admission in the

of the cracked area is bored. inside during the latching treatment.

|